Linde

- SPNA Related Products & Services » Gas for Refrigeration/Freezing

- SPNA Related Products & Services » Freezers/Chillers-Cryogenic

- SPNA Related Products & Services » Refrigeration/Freezing

- Processing/Processing Equipment » Water Treatment Equipment

- SPNA Related Products & Services » Freezing

- AQUACULTURE » Fish Farming Equipment

- AQUACULTURE » Water Treatment Equipment

- Packaging/Packaging Equipment » Modified Atmosphere Packaging

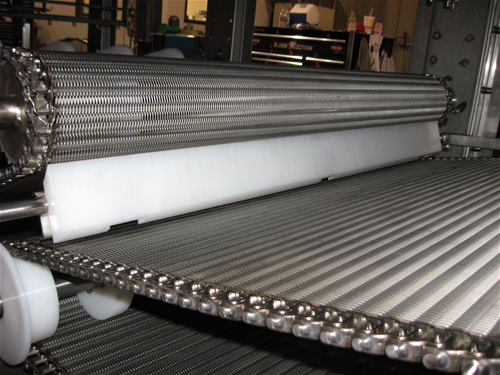

Linde’s CRYOLINE ultra performance flighted freezer optimizes heat transfer by utilizing cryogen to directly contact the individual food product pieces - think scallops, clams, shrimp or surimi. Internal freezer temperature can reach as low as – 150 degrees F depending on conditions and type of cryogen. Food products are transported through the in-line freezer at production speed. Flighted conveyors gently tumble food pieces, keeping them separate and giving them maximum exposure to the cryogen for quick and thorough freezing. Today’s food market is all about quality and convenience. Consumers want ingredients they can use to create their own special recipes. Individually quick frozen (IQF) foods provide that convenience and, when frozen quickly with liquid nitrogen or liquid carbon dioxide, the quality that is demanded. Linde’s CRYOLINE ultra performance flighted freezer takes the power of cryogenics to a whole new level by providing consumers what they want while delivering positive financials to your facility.

The CRYOLINE® PB plate belt tunnel freezer from Linde is a liquid nitrogen-powered freezer optimized to crust freeze a variety of difficult to handle products such as raw marinated proteins, sauced foods, semi-liquid products, and others. The freezer quickly produces a frozen crust on the products resulting in low- to no sticking, an easy to handle product, and an increase in yield due to the prevention of dehydration. A specially designed solid stainless-steel segmented conveyor belt is chilled in the freezer to cryogenic temperatures. As products are placed on the conveyor belt, the outside surface is quickly crust frozen by contact with the cold surface and cold airflow. This crust freezing locks-in moisture, brine, marinade, or sauces so that there are minimal losses in downstream processing steps. Adjustable high-speed internal fans and controllable gas injection optimize the flow and use of nitrogen and ensure quick and efficient product crusting. The freezer’s high capacity and efficient operation allow product yield improvement with a minimum of operating cost and plant floor space