Harpak-ULMA

85 Independence Drive

Taunton

MA

02780

United States

Looking for the lowest total cost of ownership, highest quality packaging automation solutions available for food, medical device, and other non-food producers? Customers seeking to prototype, design, build, implement and maintain packaging automation solutions rely on Harpak-ULMA. We can help you navigate today’s complex, rapidly changing packaging landscape; balancing cost and functionality with innovative or emerging processes, materials, and advanced technologies that enhance profitability and improve market performance of primary and secondary packaging operations. Our full-service solutions address installation, training, spare parts, service and customer support, while capabilities span robotics and automation, thermoforming, tray sealing, filling, flow pack, stretch, blister, skin pack, and vacuum. Our goal is to provide every G. Mondini and ULMA solution with Rockwell Automation integrated architecture and smart connectivity to reduce solution complexity and maintenance costs, while realizing better quality, capacity, and throughput. Our customers rely on us to help them optimize their overall packaging investment: Not just because we help them solve tactical production concerns with comprehensive flexible, and efficient systems, but by helping them strategize how to tackle today’s most complex packaging topics; such as sustainability, eCommerce, robotics and digital transformation.

Our full-service solutions address installation, training, spare parts, service and customer support for tray forming and sealing, robotics and automation. We aim to provide every solution with smart connectivity to reduce solution complexity and costs, while realizing better quality, capacity, and throughput while lowering your total cost of ownership.

Our full-service solutions address installation, training, spare parts, service and customer support for tray forming and sealing, robotics and automation. We aim to provide every solution with smart connectivity to reduce solution complexity and costs, while realizing better quality, capacity, and throughput while lowering your total cost of ownership.

Seafood Processing North America 2022, Seafood Processing North America 2023

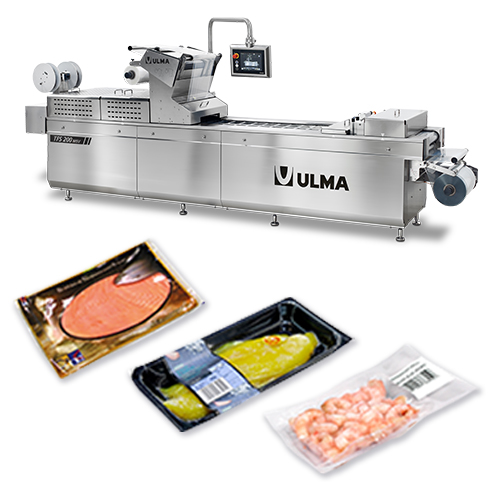

TFS 200 MSV Thermoformer

Speed and efficiency is never compromised, as the thermoformer's powerful vacuum options provide increased cycle rates of up to ten cycles per minute depending on the pack style, product and format. With environmental concerns in mind, the TFS 200 MSV is compatible with both recyclable film and paper board as well, making it the ideal packaging solution for food processors looking for more sustainable ways of protecting, transporting and displaying product from the point of harvesting or manufacture to retail outlets. Simple, straightforward tooling changes mean that it is perfectly suited to increasing production.

508-884-2500