Max Schlatterer GmbH & Co. KG

- PROCESSING EQUIPMENT » Parts/Equipment

- PROCESSING EQUIPMENT » Weighing Equipment/Scales

- Packaging/Packaging Equipment » Vacuum Packaging Equipment

- PROCESSING EQUIPMENT » Slicers

- PROCESSING EQUIPMENT » Conveyors/Conveying Equipment

- Seafood Processing Global Featured Exhibitor » Seafood Processing Global Featured Exhibitor

- PROCESSING EQUIPMENT » Separation Equipment

The Esband separator belts combine unique materials with many years of experience and know-how of Schlatterer. Due to the high quality they are perfect for applications in the food industry, especially for the separation process of meat, poultry, fish and vegetables as well as recycling. They can also be perfectly adjusted to the requirements of our customers. This is thanks to our experts and their knowledge and experience in the field. Specific Features: Abrasion-resistant coating Stable and resistant belt structure Easy to clean Temperature-resistant up to 80°C (176°F) Very good resistance to oils and greases Long-lasting Sealed edges High tear resistance

The basis of these vacuum timing belts for form, fill and seal machines is always an Esband timing belt with a winding nose on the back of the belt. This is coated in the special Esband endless process and exhibits above-average functional reliability. Thanks to tightly set manufacturing tolerances, Esband vacuum timing belts, for example, achieve optimum friction values and convince with great consistency at high frequencies. Specific Features: high functional reliability due to a high and consistent coefficient of friction high service life due to high wear resistance individual solutions possible by choice of different materials and almost unlimited special processing

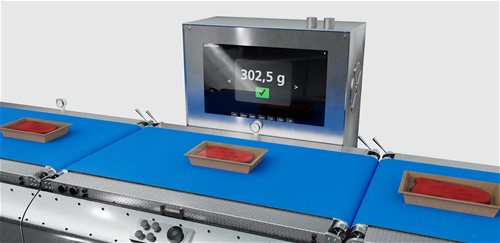

Don’t fear the scales! Esband Check Weighers are your reliable, precise and truly endless tool for checkweighing applications. The belts are produced in a literally endless manufacturing process which guarantees an absolutely homogeneous surface as well as perfect weighing results. Many of our customers have been relying on this quality in various applications for years. Specific Features: Precise weighing results Antistatic finish possible Absolute homogeneity over entire length Silicone coatings particularly temperature resistant Easy belt cleaning Resistant to microbes and hydrolysis Edge sealing

The ESBAND Silicone Pressure Rollers are used for example to hold down transport goods or to attach labels on uneven surfaces. When pressing the labels, adhesive residues may remain on the pressure rollers. The most reliable alternative in this case is the ESBAND silicone pressure roller or the ESBAND foam roller coated with silicone. Specific Features: Particularly heat resistant coatings Easy to clean and stain resistant High coefficient of friction Dimensions or cutouts individually possible according to customer requirements Small series as well as different shore hardness’s can be realized on request Pressing on labels and holding down transport goods on rising sections