Tuna farming start-up Next Tuna, which aims to be the first company in the world to produce its own Atlantic bluefin in a closed aquaculture system at a commercially viable scale, has progressed from setting abstract goals to solidifying construction dates within the past few weeks.

The company's’s research partner, the Murcia Oceanographic Center of the Spanish Institute of Oceanography, (IEO) which itself is part of the Spanish National Research Council (CSIC), recently closed the reproductive cycle of Atlantic bluefin (Thunnus thynnus) in land-based facilities – a world first. The successful closed-cycle breeding of Atlantic bluefin tuna means Next Tuna can progress its plans to construct a farm at a location north of the Spanish city of Valencia.

On 13 July, 2023, one of IEO’s Atlantic bluefin breeding stocks at its ICRA facility in Cartagena underwent hormone treatment to induce final maturation and spawning, both phases of which can elicit complications due to the stress of captivity.

Previously, industry experts had only closed the biological cycle of this species of bluefin in floating sea cages.

With land-based closed-cycle breeding achieved, IEO is now working with Next Tuna, which receives funding from both the European Union and EIT Food, on other aspects of rearing Atlantic bluefin juveniles. This includes feeding – a stage the group recognizes is key in relation to the economic viability and sustainability of tuna farming.

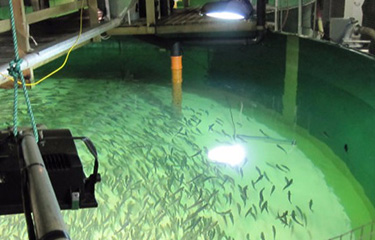

Next Tuna will draw on the latest scientific developments in Atlantic bluefin breeding and apply them in a fully controlled, floating recirculating aquaculture system (RAS) production facility. Commercial production is slated to begin in 2024 and gradually increase to full capacity by 2028, with the company looking to produce Atlantic bluefin from first feeding to a 10-kilogram transfer size.

The concept is not unlike how the salmon-farming industry produces smolts in RAS systems, though tuna breeding results in much larger fish.

Since having its own broodstock and breeding program in place is an essential part of Next Tuna’s strategy, the IEO breakthrough represents a key milestone, company co-foudners Paul-Daniel Sindilariu and Andrew Eckhardt said.

“It’s hugely important because we want to implement this production method in our facility, with our own broodstock and hatchery producing juveniles and growing them through to 10 kilograms – keeping a close eye on water quality, temperature, [and more] throughout in a floating, closed system,” Sindilariu told SeafoodSource.

The floating facility will also mitigate the logistical issues, such as moving the fish to a grow-out facility, that tuna sometimes have at sales sizes ranging from 2 to 10 kilograms. At 10 kilograms, the facility will sell the fish, which will then go to sea cages for the grow-out phase.

In the meantime, the process of getting all the necessary permits in place for the first production system is ...

Photo courtesy of Next Tuna