The United States is the latest country to grant a patent (IP 8609157) for the revolutionary process invented and developed by Chilean company Tharos for the at-sea extraction of phospholipids rich oil from krill caught in Antarctic waters.

Unlike all other extraction methods currently being used, the Tharos principle doesn't use solvents and therefore leaves no residue in the final product. Dimitri Sclabos, general manager of Tharos and one of the inventors of the process, said: "We believe this to be a twice revolutionary concept because it is highly cost efficient and because all current processes used to extract phospholipids rich krill oil are done on land and use solvents. Our process is chemical free."

Tharos filed for a patent for its extraction process under PCT (Patent Cooperation Treaty) in 2009 and so far it has been granted in several countries including China and Ukraine as well as the United States where it was published last week. "We made more than 15 national applications," Sclabos said. "We are still being reviewed in other countries as part of the normal grant process."

Tharos has been advising on the utilization of krill (Euphasia superba), the tiny crustacean found in huge quantities in the Southern Pacific Ocean for the past 25 years. Although attempts have been made to use the body of the animal for direct human consumption, these have so far not proved financially attractive, and it is the oil, an excellent source of omega-3 fatty acids and the antioxidant astaxanthin, which is now prized by both the pharmaceutical and food industries.

"Krill oil is the best source of phospholipid enriched omega-3 oils in the world," Sclabos said. "Phospholipids, a major component of human cell membranes, play a major role in human health so phospholipids rich krill oil is highly sought after by the nutraceutical (supplements) and pharmaceutical industry which currently sells it mostly in capsule form."

Although Sclabos estimated that virtually all of the oil extracted from krill caught in the Southern Pacific Ocean is used in capsule form, food fortification is gaining market share, he said. "It [krill oil] is used as an ingredient in foods such as milk, and yogurt."

At present several processes are used to extract oil from krill and not all of them produce phospholipids-rich oil. In fact, the traditional at-sea method manufactures lower-priced, triglycerides-enriched oil.

Phospholipids-rich oil is currently produced on land from dried krill meal or whole frozen krill. These methods all involve the use of solvents, and while Sclabos admitted that pharma-grade krill oils can be extracted using solvents, he said some residues may remain in the final product.

"Such residues might be well within market regulation, but we think that a no-residue process is a much more valuable proposition to the end user. Our method eliminates the solvent application to get a quality krill oil with no residues at all and with a pharma-quality grade."

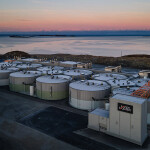

Furthermore, Sclabos said there are additional benefits to be gained from using Tharos' new extraction process. "The krill oils will be entirely manufactured at sea. Processing immediately on board the catching vessel will improve the quality of the oils. It will prevent deterioration and cross contamination, preserve freshness and keep krill's natural compounds readily available for human consumption."

Not only will the quality of the krill oils enriched with phospholipids produced at sea on board the catching vessel surpass that of oils produced by other methods, according to Tharos, the company claims that its patented extraction process will significantly reduce the costs of producing krill oil at sea.

"This invention will also protect the resource as fishing will not be focused on the period when the oil content of krill is higher than it is at other times of the year," Sclabos said.